We’ve received much improved samples for our two injection mould projects and they are both ready for the next phase of tooling and payment of additional deposits. The next phase is geared towards improving the final appearance and qualities that make the product eye-catching and realistic.

We try very hard to bring out the best possible product, none of this is possible without support from the end-user and prototype modeller.

Stanchions – we started this project (DP 6150) this summer after an ill-fated attempt to use a new supplier for the injection mould tooling. While we still have some hurdles to pass to clean up the mould and make a great product, you can see from the test shot, we’re well on our way. The stanchions are going to moulded with ABS plastic for strength. The top of the part will be cored from both sides which enable you to easily replicate the handrails with wire. We have two wire handrail kits ready for production, more will follow these initial releases.

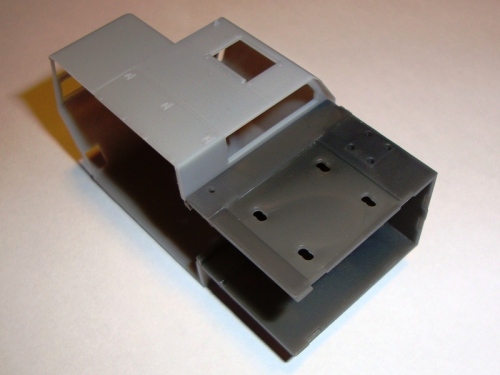

Clean Air Rooms – the tooling for the Clean Air Rooms was started in the late summer with a great sales effort from our supporters. The Clean Air Room Base (MK5000) is an injection moulded product that enables you to layer photo-etch sides to replicate with exact detail, any GP35, GP38, GP39, GP40, GP15-1, GP38-2, GP39-2, GP40-2, GP50 and the late GP39-2 phases of Clean Air Room that were used by the ATSF. Our other kit, (MK5001) is good for the SD family, SD38, SD39, SD40, SD45, SD38-2, SD40-2, and SD45-2.

All of these projects were made possible with the strong support of a few dedicated modelers this summer, please continue your efforts to use our products in your modelling and we will send more exciting products your way.

Christopher Howard

President, Railflyer Model Prototypes Inc.

Looks great Chris

By: gtwhogger on December 21, 2010

at 11:31 am